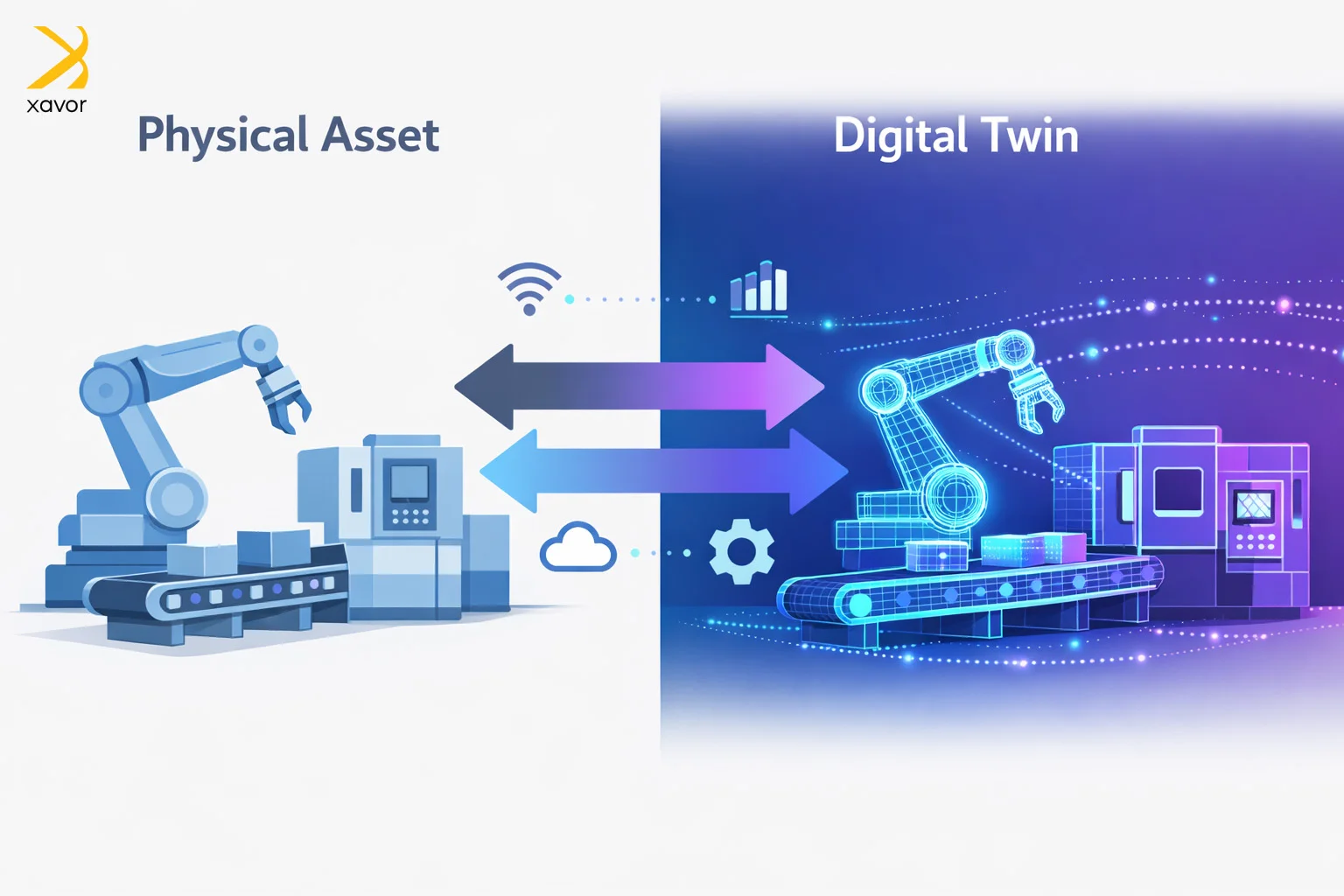

Producers are more and more adopting digital twins and Bodily AI options. A digital twin is a real-time digital mannequin of a bodily asset, product, or course of. IT helps groups monitor efficiency, consider circumstances, determine points early, and enhance operations extra successfully.

McKinsey notes that with a powerful digital twin platform, firms can run full product simulations in a digital setting earlier than the shopper approves the ultimate design. This highlights why digital twins are gaining traction in manufacturing.

Digital twins are additionally enhancing product growth. By replicating actual programs digitally, organizations can work sooner, make higher choices, improve productiveness, and scale back prices by addressing issues earlier within the cycle.

Market progress displays this momentum. Grand View Analysis studies that the digital twin market was valued at $16.75 billion in 2023 and is projected to attain $155.84 billion by 2030, with a CAGR of 35.7% from 2024 to 2030. With progress like this, digital twins are anticipated to play an excellent bigger position in manufacturing within the coming years.

Now, let’s discover the important thing advantages of digital twins and probably the most impactful use instances driving their adoption.

What are digital twins?

In manufacturing, a digital twin is a digital illustration of an actual system, machine, or course of. IT works like an in depth digital mannequin of a manufacturing facility ground, constructed to mirror actual working circumstances and predict how modifications could have an effect on outcomes.

Manufacturing groups use digital twins to plan, research, and enhance processes in a simulated setting. This permits them to check concepts and optimize efficiency with out counting on expensive bodily trials or disrupting work on the store ground.

Historical past and evolution

Digital twins started with CAD instruments, which enabled engineers to create detailed digital drawings and fashions of actual objects. As computer systems grew to become sooner and sensors grew to become extra superior, these easy fashions developed into good simulations that might replace in actual time utilizing real-time information.

By the early 2010s, digital twins grew to become standard in industries resembling aerospace and automotive as a result of these fields take care of advanced machines that require very excessive accuracy and reliability.

A breakthrough occurred when NASA started utilizing digital twins to observe and keep spacecraft. This helped NASA hold spacecraft protected and working correctly in the robust circumstances of house. NASA’s success demonstrated how highly effective digital twins can be, and extra industries started utilizing them as properly.

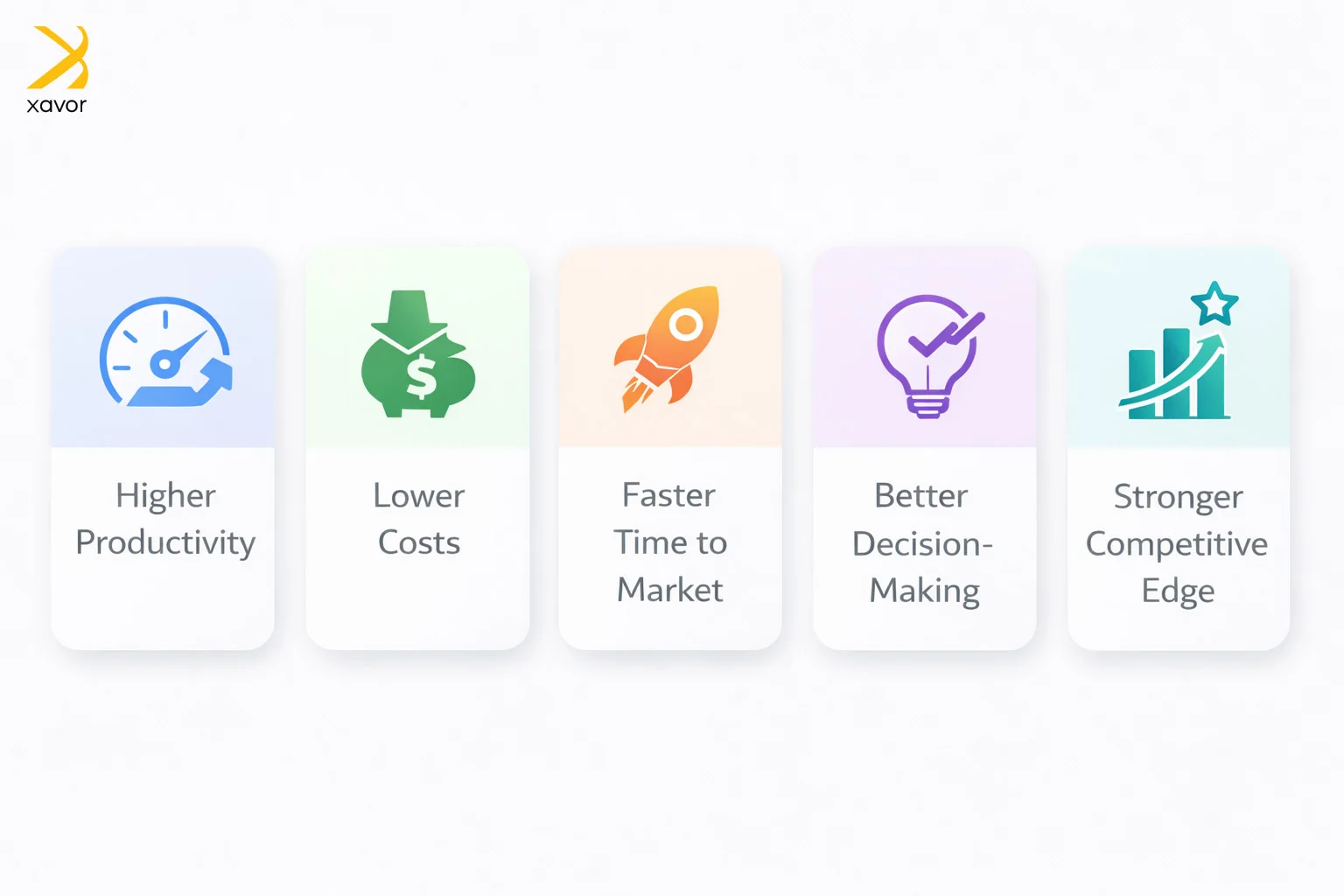

Digital twins advantages in manufacturing

1. Greater productiveness

Actual-time digital fashions assist determine inefficiencies early. Groups can check course of enhancements in a simulated setting. This reduces downtime and will increase total output.

2. Decrease prices

Stay monitoring helps higher upkeep planning. Predictive insights assist stop failures earlier than they disrupt manufacturing. Much less waste and fewer breakdowns result in significant value financial savings.

3. Sooner time to market

Digital prototyping makes IT simpler to validate designs rapidly. Product modifications may be examined earlier than any bodily construct begins. This shortens growth cycles and hurries up launches.

4. Higher decision-making

Correct operational information improves visibility throughout programs. Analytics spotlight efficiency developments and potential dangers. Leaders can act sooner with clearer, data-backed instructions.

5. Stronger aggressive edge

Better agility helps producers reply to shifting calls for. Steady optimization improves effectivity over time. A future-ready method helps long-term progress and resilience.

Digital twins in manufacturing: Prime use instances

Digital twins are serving to producers perceive their operations extra clearly. They create a digital model of an actual machine, product, or course of. This makes IT simpler to trace efficiency and discover issues that is likely to be missed in any other case. As soon as the difficulty is seen, groups can simulate totally different digital manufacturing options and select the very best one. That method reduces guesswork and helps higher outcomes.

1. Predictive upkeep and lowered downtime

One of many strongest functions of digital twins is predictive upkeep. Not like reactive upkeep, which causes costly surprising stoppages, or preventive upkeep, which may result in changing components too early, digital twins constantly observe tools conduct and forecast points earlier than breakdowns occur.

Instance: A shopper electronics firm used digital twin fashions to guage a brand new product’s aerodynamics and warmth dissipation. The insights helped optimize the design 20% sooner, reducing growth prices and enhancing reliability.

2. Digital prototyping and smarter product design

Constructing new merchandise the normal approach usually requires a number of bodily prototypes, which provides value and time. Digital twins rework this course of by enabling digital prototypes and reasonable simulations lengthy earlier than any bodily construct is required.

Instance: A shopper electronics firm utilized digital twin simulations to check a brand new product’s aerodynamics and thermal efficiency. This accelerated design refinement by 20%, decreasing prices whereas boosting product sturdiness.

3. Good manufacturing facility and course of optimization

Producers use digital twins to fine-tune manufacturing traces and strengthen operational efficiency. By constantly evaluating machine output, materials motion, and power utilization, digital twins allow real-time course of changes and elevated productiveness.

Instance: A worldwide meals processing agency carried out digital twins to simulate and enhance packaging-plant workflows. By recognizing bottlenecks earlier than making on-site modifications, the corporate elevated manufacturing output by 15% with out investing in new infrastructure.

4. Distant monitoring and management for distributed operations

As manufacturing turns into extra international, distant visibility and management are more and more vital. Digital twins allow groups to supervise a number of websites from wherever, enhancing coordination, consistency, and operational continuity.

Instance: A pharmaceutical firm monitored international manufacturing websites by digital twins. When an issue surfaced at a distant facility, engineers made real-time distant changes to keep high quality and compliance with out being on-site.

5. Provide chain resilience and logistics optimization

Provide chain effectivity, getting hindered because of disruptions, is a persistent problem in manufacturing. Digital twins assist by simulating logistics, stock, and provider efficiency in actual time, enabling groups to anticipate dangers and reply extra rapidly when disruptions happen.

Instance: A multinational automotive firm used a digital twin of its provide chain to determine alternate suppliers throughout disruptions. This lowered supply delays by 40% throughout a world disaster.

6. Sustainability and power effectivity

Digital twins play a key position in reducing environmental impression and assembly sustainability targets. By monitoring power use, materials consumption, and waste, producers could make data-backed choices that scale back emissions and enhance effectivity.

Instance: A semiconductor producer used digital twins to optimize cleanroom power consumption throughout fabrication amenities. Dynamic HVAC and filtration changes primarily based on real-time circumstances lowered power utilization by 18%, decreasing prices and supporting sustainability objectives.

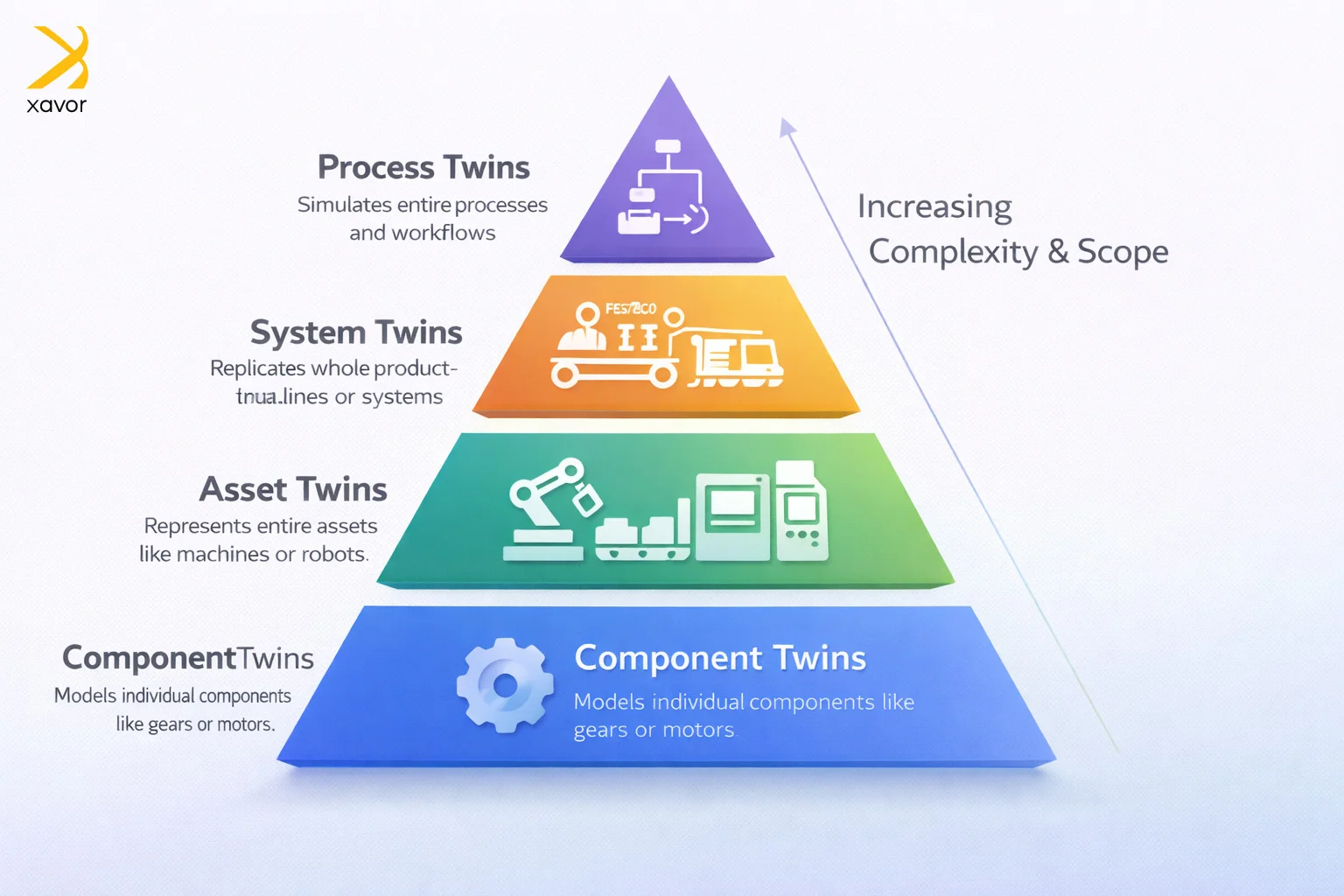

What are the differing types of digital twins?

Digital twins are available differing types, relying on what you need to mannequin. Every sort focuses on a unique degree in manufacturing, from small components to full processes.

1. Part twins (Components twins)

These are digital copies of single components or parts. They assist you to perceive how one half performs, how lengthy IT will final, and the way to enhance its design and high quality.

2. Asset twins

These are digital copies of machines or gadgets. They assist firms monitor tools in actual time, discover issues early, and enhance efficiency utilizing predictive upkeep.

3. System or unit twins

These are teams of machines working collectively, resembling a full manufacturing line. They assist you to see how totally different machines work together and the place delays or bottlenecks happen.

4. Course of twins

These simulate the total manufacturing course of from begin to end. Firms use them to check totally different situations, enhance workflows, and optimize operations with out disrupting actual manufacturing.

Every sort is beneficial for a selected goal, whether or not IT’s enhancing an element, preserving machines operating easily, rushing up manufacturing traces, or optimizing the whole course of.

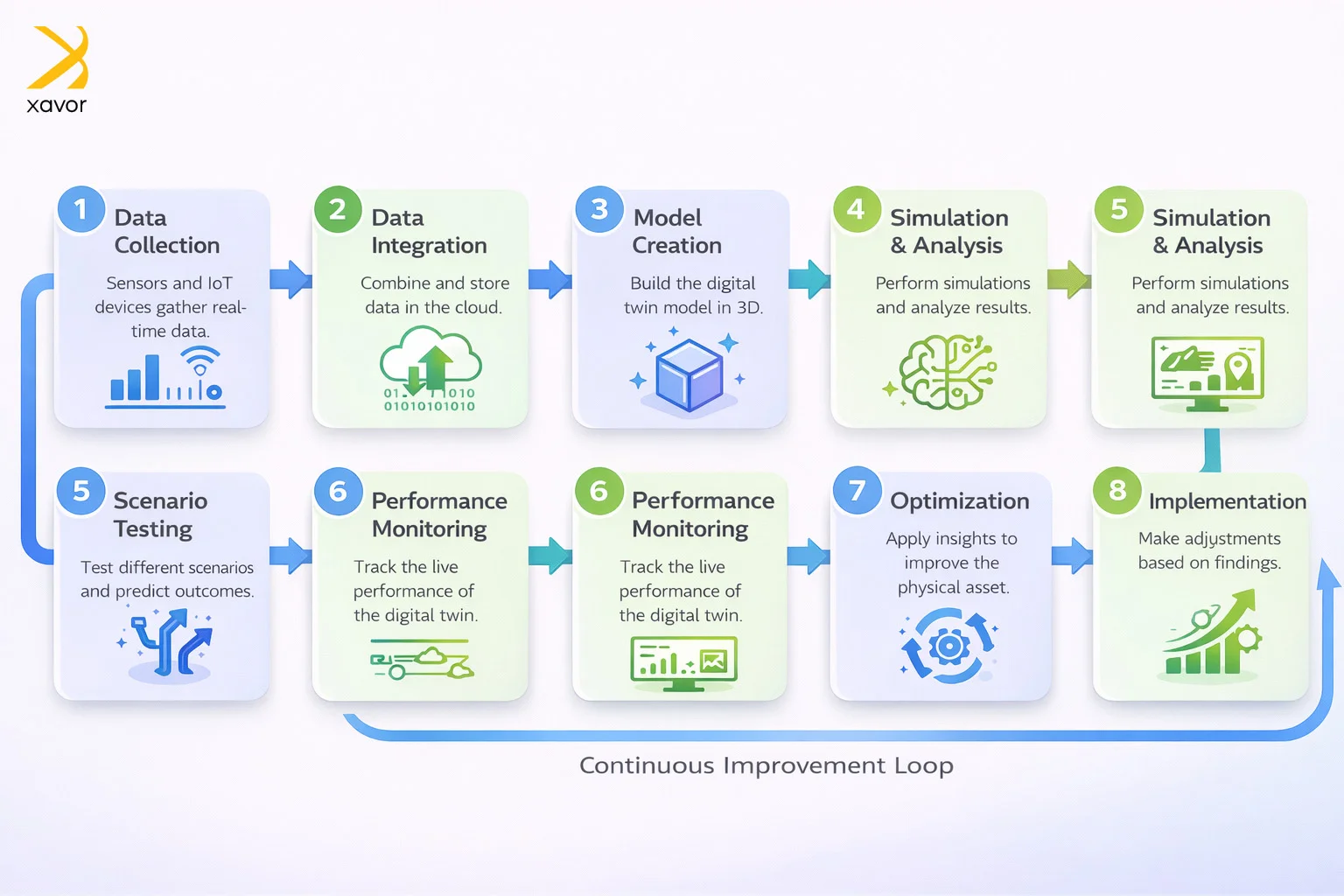

How do digital twins work in manufacturing?

Digital twins work by making a digital copy of an actual machine or system and preserving IT synchronized with dwell information. Right here’s how IT occurs.

Step 1: Knowledge assortment

Sensors are put in on the bodily asset to seize key working information, resembling:

- temperature

- stress

- vibration

- pace

Step 2: Knowledge integration

That sensor information is distributed to an IoT platform, which collects IT in a single place and retains IT accessible in actual time. That is what connects the true asset to its digital twin.

Step 3: Digital mannequin creation

Software program then builds a digital mannequin of the asset utilizing the incoming information. The mannequin updates constantly, so IT at all times matches what’s occurring in the true world.

Step 4: AI and machine studying

AI instruments analyze each historic and dwell information to:

- spot patterns

- predict future efficiency

- warn about attainable points early

Step 5: Simulation and prediction

The digital twin can run “what if” assessments to foretell failures and discover higher methods to function. This helps plan upkeep earlier than breakdowns occur and reduces downtime.

Step 6: Visualization and consumer interplay

A properly designed dashboard makes the digital twin straightforward to make use of. IT lets groups monitor efficiency, view outcomes clearly (usually with 3D visuals), and discover simulation outcomes.

Step 7: Suggestions loop

The bodily asset and digital twin constantly share Information. The true asset updates the dual, and the dual gives insights that enhance actual operations.

Step 8: Steady enchancment

Over time, firms use the digital twin to seek out inefficiencies, check enhancements just about, and apply the very best modifications in the true system.

Digital twins in manufacturing firms

1. Tesla

Tesla makes use of digital twin Technology to enhance manufacturing facility operations and car efficiency. Every Tesla car is paired with a digital twin that collects information all through its lifecycle, from manufacturing by on a regular basis driving. That Information helps design enhancements, helps anticipate upkeep wants, and contributes to a greater possession expertise.

2. BMW

BMW makes use of digital twin Technology to strengthen its car manufacturing operations. These digital fashions simulate assembly-line exercise, enabling groups to refine workflows, enhance precision, and increase effectivity. Consequently, BMW can scale back manufacturing errors and keep larger, extra constant construct high quality.

This additionally applies digital twins to check car conduct in several driving and environmental circumstances. This gives engineers with dependable information to information security enhancements and improve the shopper expertise. Digital twins additionally help the design and validation of recent options and applied sciences, which shortens growth timelines and helps BMW convey improvements to market sooner.

3. Basic Electrical (GE)

GE makes use of digital twins to monitor and keep jet engines. Every engine has a digital mannequin that receives real-time sensor information, tracks efficiency, and predicts when upkeep is required. This method has lowered unplanned upkeep by 40% and elevated engine uptime, which results in fewer disruptions in operations.

GE additionally makes use of digital twins to enhance gas effectivity and scale back emissions. The info helps engineers detect early warning indicators of damage or efficiency loss, to allow them to schedule fixes earlier than a failure happens. This improves reliability and might prolong the service life of every engine.

Conclusion

Digital twins have gotten a key software in manufacturing as a result of they create a real-time digital mannequin of belongings and operations. This mannequin updates with dwell information, which helps groups detect issues early and predict failures earlier than downtime occurs. IT additionally helps digital testing, which reduces the necessity for expensive bodily trials and hurries up product growth.

Over time, digital twins enhance productiveness and scale back waste. They strengthen decision-making by clearer operational visibility. In addition they help power effectivity and assist producers keep resilient in provide chain disruptions. If you wish to discover how digital twins can enhance your manufacturing efficiency, Xavor can assist you intend, construct, and scale the precise answer. Contact us at [email protected].

FAQs

A digital twin provides producers a real-time digital view of machines, manufacturing traces, or complete processes utilizing dwell information. This helps groups spot inefficiencies early, predict failures earlier than downtime occurs, and check enhancements just about earlier than making use of modifications on the store ground.

You usually want sensors (or one other dependable information supply) to maintain a digital twin up to date with real-world circumstances. AI and machine studying aren’t required to construct a primary twin, however they enormously improve worth by figuring out patterns, predicting failures, and recommending optimizations, particularly for predictive upkeep, course of enchancment, and power effectivity.

Most producers begin the place ROI is quickest and information is best to gather, resembling: 1) Predictive upkeep for essential tools to cut back unplanned downtime. 2) Course of optimization on a bottlenecked manufacturing line to enhance throughput. 3) Digital prototyping to validate designs earlier and shorten time to market

👇Comply with extra 👇

👉 bdphone.com

👉 ultractivation.com

👉 trainingreferral.com

👉 shaplafood.com

👉 bangladeshi.help

👉 www.forexdhaka.com

👉 uncommunication.com

👉 ultra-sim.com

👉 forexdhaka.com

👉 ultrafxfund.com

👉 bdphoneonline.com

👉 dailyadvice.us